11 December, 2025

11 December, 2025The ATILA research project, funded by the Spanish Ministry of Science and Innovation, the State Research Agency, and the European Union, has successfully validated Meltio’s metal additive manufacturing technology for producing hip and knee bio-implants in titanium alloy. The consortium, led by the AIDIMME Technological Institute, includes the participation of Valencia General University Hospital (FIHGUV), the University of Salamanca (ALF USAL group), and Meltio.

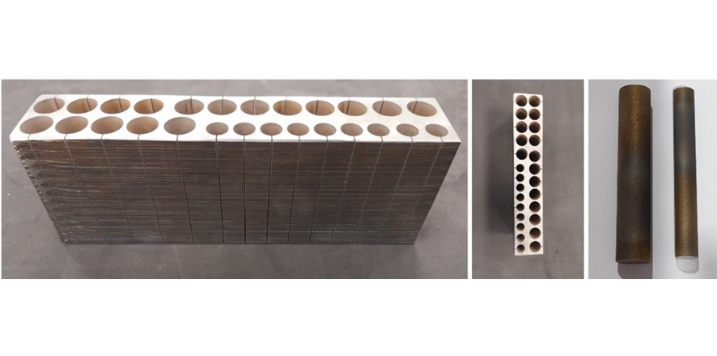

Throughout 2025, the team focused its work on three biomedical demonstrators: the acetabular cup (hip implant), the tibial tray, and the femoral component (knee implants). These parts were manufactured using DED-LB/M technology (directed energy deposition with wire and laser), employing welding wire as feedstock—a more sustainable material with lower waste generation than metal powder.

Characterization tests carried out on Ti6Al4V Grade 23 titanium confirm that the produced parts meet the ASTM and UNE standards required for biomedical implants, without the need for additional heat treatments. In parallel, biocompatibility studies coordinated by BTELab at FIHGUV are progressing toward in vitro and in vivo validation of the manufactured samples.

The project also includes numerical simulation of the deposition process, led by the University of Salamanca, aimed at optimizing thermal and process parameters. With these results, ATILA is positioning itself as a national benchmark in applying wire-laser metal 3D printing to the biomedical field.

Subscribe to our newsletter. Just insert your e-mail and you will receive the latest news.