24 July, 2020

24 July, 2020The AZTERLAN technology center leads the SUSIE consortium in which TECNALIA, TEKNIKER, MU, UPV / EHU and INVEMA, AFM Clusters technology unit, also participate.

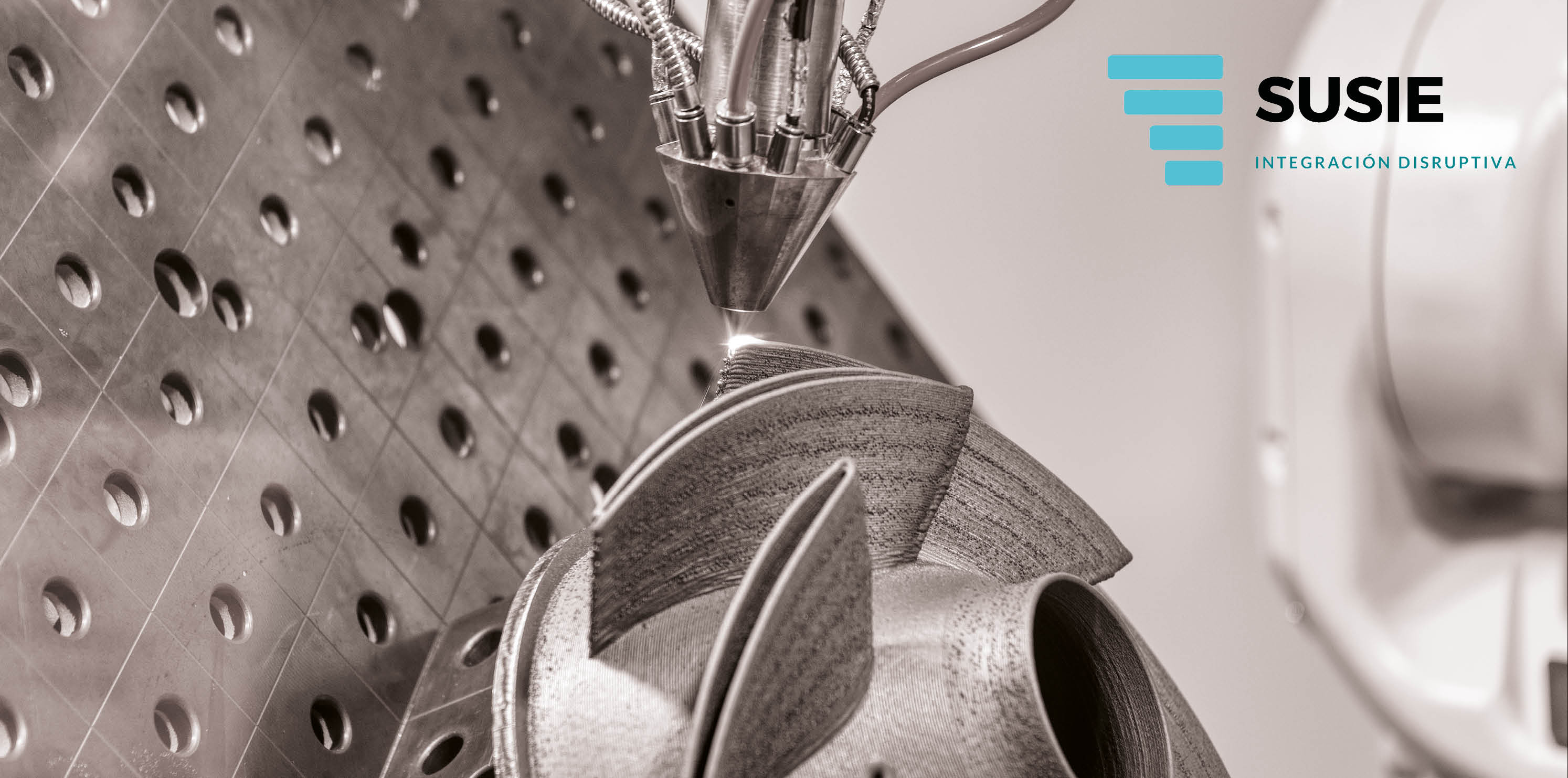

The SUSIE project has the global objective of solving the technological challenges posed by the collection of data from the most inaccessible areas on the surface of tools for transforming metal, plastic and ceramic materials.

In industrial processes, the most critical processes often occur in unreachable locations for sensors and transducers. As a consequence, on countless occasions its measurement is carried out indirectly, these variables being the ones that feed the data processing, simulation and decision-making systems at the factory.

To achieve this aim, it structures its technological objectives into four concepts:

The expected results when the project is finished by the end of 2021 would be:

Advances in POWER AND SIGNAL

Resolution of the problems associated with the fusion and short circuit of the electrical lines and the breakage of the optical lines necessary for the operation of the sensors thanks to the ability to adjust the combination of cable protection, recharge material and laser cladding / thermal spraying parameters to encapsulate cabling immediately under any steel surface.

Advances in COOLING

Solving problems associated with heat dissipation during the integration process and during service in cases where tools work hot.

Advances in PROTECTION

The main result in terms of sensor integration is to maintain its integrity at the end of the process.

INTEGRATION strategies

Solve the integration of the main scientific-technological challenges applying use cases oriented to future applications

The biannual SUSIE project is one of the projects supported by the Basque Government's ELKARTEK 2020 program, and has a budget of 612,000 euros.

AZTERLAN, TECNALIA and TEKNIKER technology centers, in close collaboration with MU and UPV / EHU universities, work on the technical developments of the project, while INVEMA, as Supply / Demand Intermediation Agent within the Basque Science and Technology Network, will carry out dissemination and contrast activities with the industrial environment.

Subscribe to our newsletter. Just insert your e-mail and you will receive the latest news.