12 November, 2020

12 November, 2020CEMAP is a project led by Basque technology centers and universities that aims to develop new materials and increase the region’s differentiation. Its primary objective is to cover the primary needs of the region’s industrial base by offering high added value solutions that differentiate it from other regions in Europe, thereby placing Basque companies in a more favorable position as well as engaging in training and coordinating various assets in the Advanced Materials Node of the Basque Digital Innovation Hub.

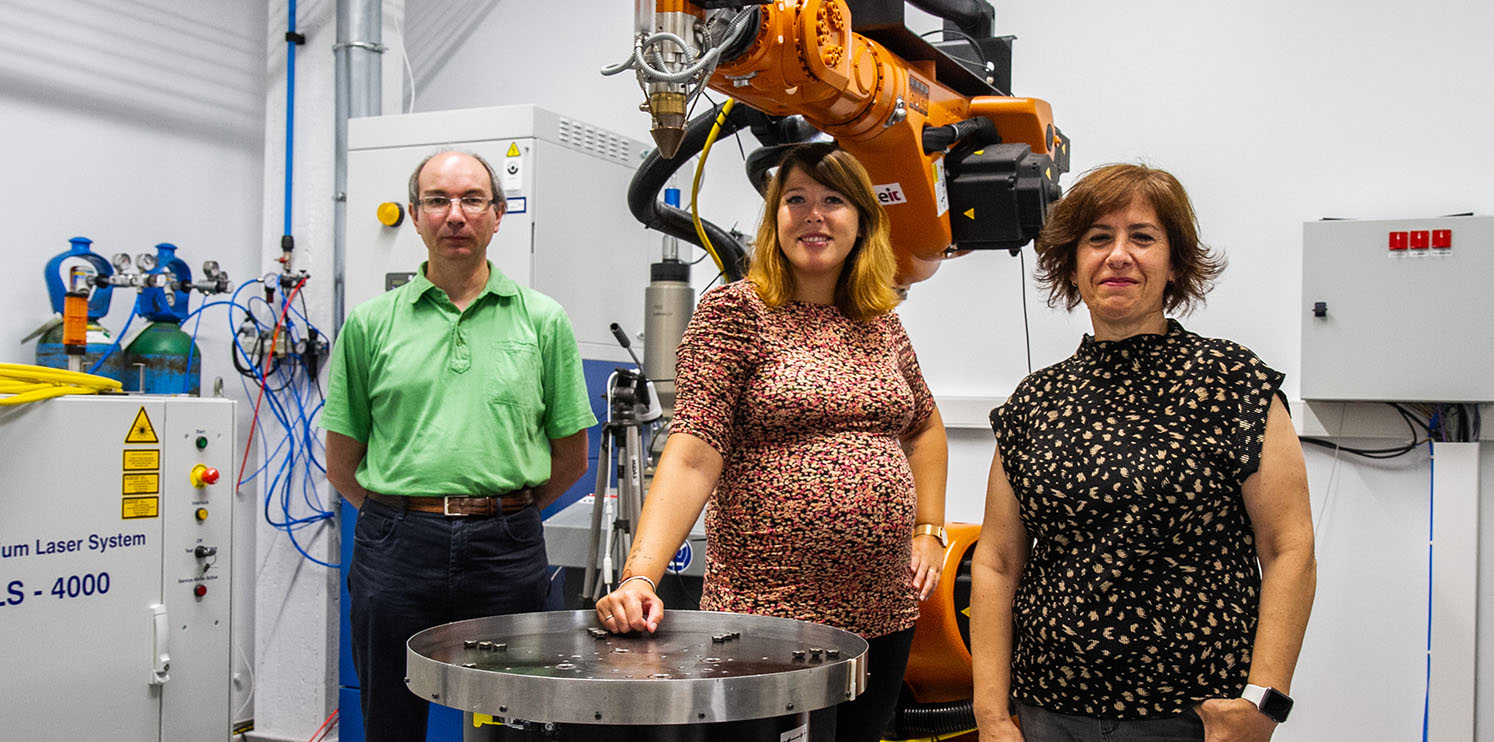

The project consortium, led by Ceit, also includes the technology centers Azterlan, Tecnalia, Lortek and Tekniker (all members of the Basque Research and Technology Alliance), the University of the Basque Country’s Department of Condensed Matter Physics, the School of Engineering in Bilbao, and the Department of Materials Physics and Magnetism research group, Mondragon University’s Faculty of Engineering, and the R&D unit at Eibar Precision Casting. This consortium is tackling the challenge of developing new advanced materials with high added value as well as improving existing production processes, especially for the transportation, aeronautics, energy and machine tool sectors.

CEMAP's specific objectives are to:

The CEMAP project’s consortium, which is made up of members of the Basque Science and Technology Network, hopes to position itself at the forefront of European R&D and innovation groups in the field of advanced materials and latest-generation manufacturing technologies.

Subscribe to our newsletter. Just insert your e-mail and you will receive the latest news.