19 November, 2024

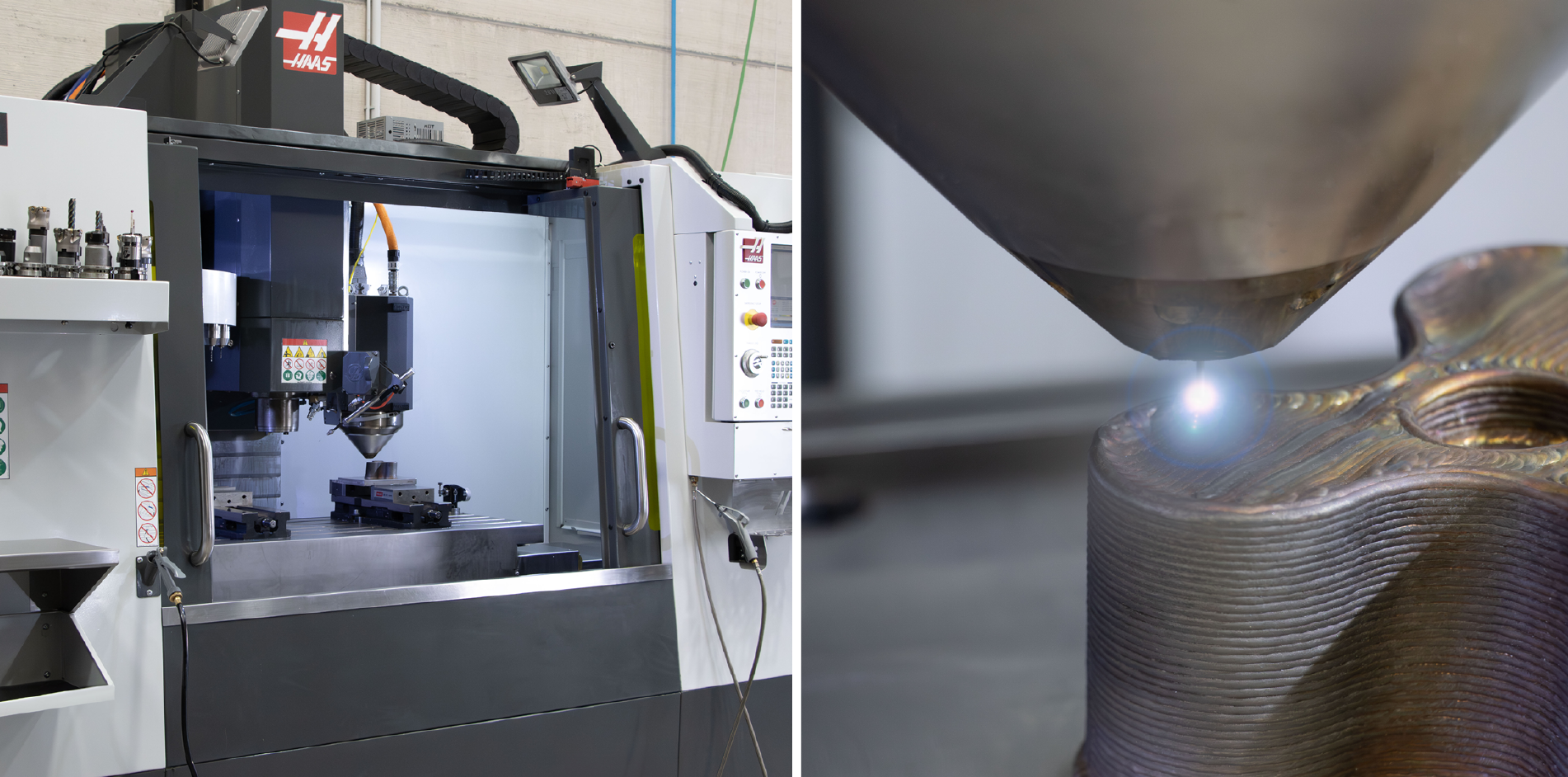

19 November, 2024Meltio, a leader in directed energy deposition (DED) technology and creator of the Meltio M600 industrial metal 3D printer, has introduced the Meltio Engine Blue, a groundbreaking integration system designed to optimize the production of metal parts. The system, launched during Formnext 2024 in Frankfurt, Germany, enables seamless integration with industrial robotic arms and vertical machining centers, advancing the adoption of metal additive manufacturing technologies.

The Meltio Engine Blue builds upon its predecessor, the Meltio Engine with infrared lasers, offering simplified integration and significantly increased deposition rates. With a 1.4 kW blue laser head, the system eliminates the need for complex components like fiber optics and collimators, reducing maintenance times and enhancing operational reliability.

"This innovation addresses the needs of our industrial customers by providing greater reliability, shorter downtimes, and optimized performance for handling complex materials such as titanium, copper, and aluminum," said Alejandro Nieto, Product Manager at Meltio.

The Meltio Engine Blue introduces a host of advancements that make it a standout solution in the metal additive manufacturing market:

The Meltio Engine Blue is tailored to meet the needs of industries such as automotive, aerospace, energy, marine, mining, and defense. Its ease of integration, coupled with high reliability and efficiency, makes it an essential tool for producing high-quality metal parts in demanding environments.

These features enable businesses to lower operating costs, increase productivity, and handle complex materials in more agile and sustainable processes.

At Formnext 2024, Meltio’s booth features unique metal parts created using the Meltio Engine Blue’s wire-laser technology. These include components manufactured with innovative materials like marine bronze and dual-wire alloys, as well as multi-material parts produced on a single build plate using up to four different materials, including tool steel, mild steel, marine bronze, and stainless steel.

With the Meltio Engine Blue, the company reaffirms its commitment to advancing metal additive manufacturing, cementing its position as a global leader in industrial innovation.

Subscribe to our newsletter. Just insert your e-mail and you will receive the latest news.