15 March, 2024

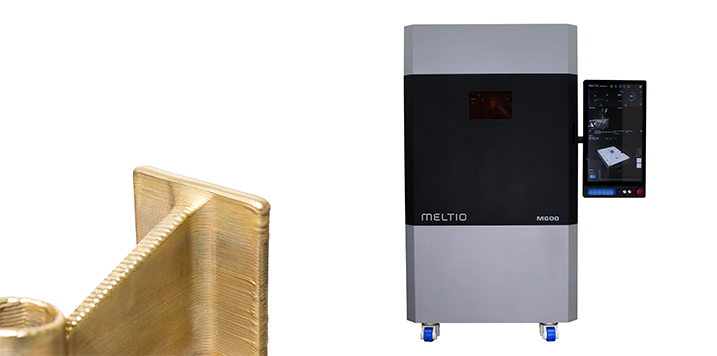

15 March, 2024Meltio, the renowned Spanish multinational and pioneer in the additive manufacturing sector, has unveiled its latest technological breakthrough, the Meltio M600 3D printer. This innovative machine, set to revolutionise the manufacturing industry, has been designed to overcome current production challenges by facilitating the adoption of metal additive manufacturing in machine shops and industrial sectors such as automotive, aerospace, defence, mining, oil and gas.

Designed and manufactured at Meltio's newly expanded facility in Linares, Jaén, the M600 aims to solve critical industry issues such as long lead times, high inventory holding costs and fragile supply chains. This machine not only increases productivity and reduces manufacturing costs but, thanks to its unique metal 3D printing technology, allows 24/7 autonomous operation with minimal human intervention.

This launch follows the recent agreement between Meltio and Sicnova to support the digitisation of the Spanish Ministry of Defence and highlights Meltio's evolution since its collaboration with the US Navy, underlining its commitment to innovation and the practical application of 3D printing in demanding contexts.

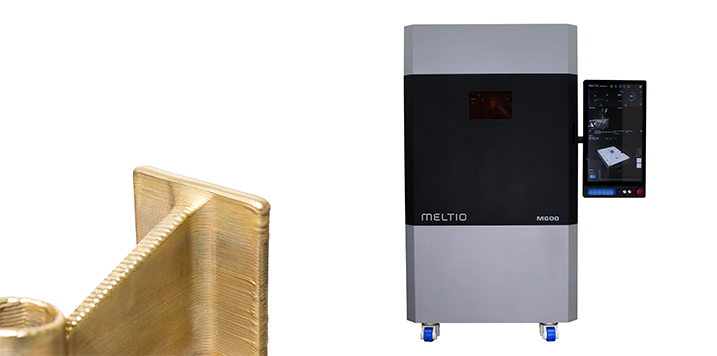

The Meltio M600 stands out for its use of welding wire as a raw material, which represents a significant advantage in terms of cost, safety and quality compared to powder-based 3D printing techniques. In addition, it introduces a new-generation blue laser deposition head that improves printing efficiency, particularly on reflective metals such as aluminium and copper.

Designed to integrate seamlessly with existing CNC machines, the M600 offers a flexible and efficient production solution, capable of adding or repairing features on existing parts as well as manufacturing new ones. Its autonomy and ease of use are enhanced by the elimination of manual processes and the incorporation of Meltio Horizon software, which simplifies programming.

The relevance of the Meltio M600 transcends multiple industries thanks to its adaptability, print quality and reduced material waste, proposing a viable solution for modern manufacturing seeking flexibility, efficiency and sustainability.

The practical application of this technology has been demonstrated in collaboration with Cementos La Cruz, where the printing of a stainless steel nozzle using the M600 has enabled progress towards more sustainable construction. This case underlines the versatility and potential of metal 3D printing in improving processes and products in a variety of industries.

With technical specifications including a build area of 300 x 400 x 600 mm, closed process control and a three-stage filtration system, the Meltio M600 is shaping up to be a milestone in additive manufacturing, aiming to set a new standard in industrial production.

15 March, 2024Meltio, the renowned Spanish multinational and pioneer in the additive manufacturing sector, has unveiled its latest technological breakthrough, the Meltio M600 3D printer. This innovative machine, set to revolutionise the manufacturing industry, has been designed to overcome current production challenges by facilitating the adoption of metal additive manufacturing in machine shops and industrial sectors such as automotive, aerospace, defence, mining, oil and gas.

15 March, 2024Meltio, the renowned Spanish multinational and pioneer in the additive manufacturing sector, has unveiled its latest technological breakthrough, the Meltio M600 3D printer. This innovative machine, set to revolutionise the manufacturing industry, has been designed to overcome current production challenges by facilitating the adoption of metal additive manufacturing in machine shops and industrial sectors such as automotive, aerospace, defence, mining, oil and gas.