01 July, 2021

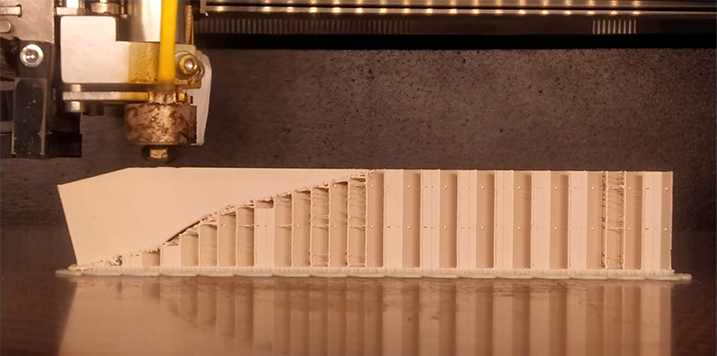

01 July, 2021The technological centre GAIKER, a member of the Basque Research & Technology Alliance (BRTA), is taking part in the FUND3D project, financed by the Ministry of Science and Innovation scheme Retos Colaboración, the aim of which is to develop and validate 3D printing and post-processing materials for building functional moulds or tools for industrial application. This research is largely focused on developing new thermoplastic compounds and post-treatments to improve dimensional stability, thermal and machining performance and electrical and thermal conductivity.

An increasing number of businesses are incorporating open-code industrial printing equipment into their production processes in order to optimise their processes and shorten the time to market of their new products and services, leading to a need for technical 3D printing materials.

FUND3D was set up in 2018 to address this need. This project is currently in its final stage, which entails working on obtaining and validating demonstrators of the tools obtained by 3D printing with the materials and after-treatments studied and developed. To reach this final stage, different lines of research have been undertaken over three years of work:

ELIX Polymer, FLEXIX and IKOR, is in charge of developing 3D printing materials and after-treatments to obtain printed tools. GAIKER possessed extensive experience and resources to tackle development through compounding and extrusion of filaments for 3D printing with FFF/FDM technology. It also has the necessary resources to characterise the materials and products to be printed and desktop and professional printers to assess the printing capacity of the materials and tackle the development of products with both thermoplastic commodities and with composites and high-performance technical thermoplastics.

Subscribe to our newsletter. Just insert your e-mail and you will receive the latest news.