12 November, 2025

12 November, 2025Sintering-based additive manufacturing technologies, such as Binder Jetting, face a critical technical challenge: achieving high dimensional accuracy in the final parts. During the sintering process, components undergo shrinkage and deformation that are difficult to predict and control, making serial production difficult and increasing costs during early-stage development.

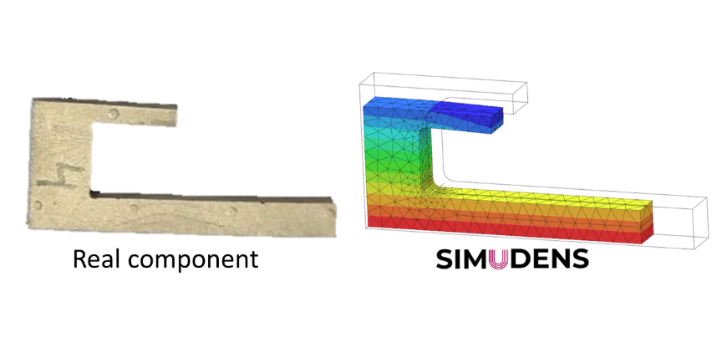

To address this issue, technology center CEIT has developed SIMUDENS, an advanced digital simulation tool capable of accurately modeling the sintering process. Using detailed physical models, the software predicts how the shape and dimensions of a part will evolve, accounting for key factors such as material densification, gravitational effects, and friction with support surfaces.

This predictive capability enables users to optimize the geometry of the “green” part, compensating in advance for the deformations that will occur during sintering. As a result, final components meet Near Net Shape (NNS) tolerances from the first production attempt.

The use of SIMUDENS leads to significant improvements in process efficiency and sustainability. It reduces development time and raw material waste, while increasing repeatability—key requirements for the industrial-scale adoption of sintering-based additive manufacturing.

With this development, CEIT strengthens its role in advancing digital tools that enhance the performance and reliability of complex manufacturing processes within the framework of advanced production technologies.

Subscribe to our newsletter. Just insert your e-mail and you will receive the latest news.