20 October, 2025

20 October, 2025AIMPLAS, the Spanish Plastics Technology Centre with over 35 years of experience, will present its latest developments in additive manufacturing materials at Formnext 2025, where it will exhibit at Stand 12.0 C121. The institute operates more than 35 pilot plants dedicated to plastics processing, supporting material formulation and process innovation across the entire plastics value chain.

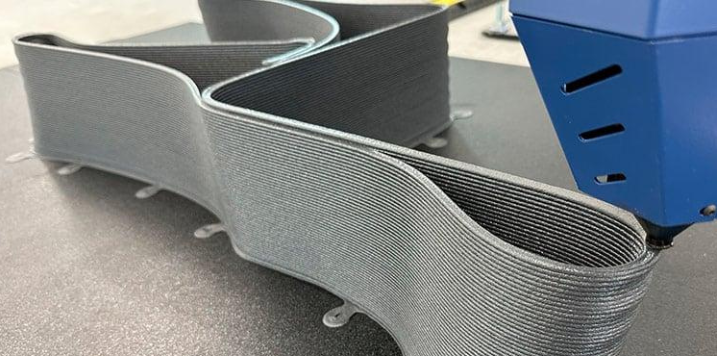

Among the key highlights is the MAT3D-XL project, focused on developing recycled or biobased thermoplastic compounds reinforced with fibers such as carbon, glass, or natural alternatives. Designed for large-format 3D printing, these materials aim to enhance the mechanical performance of printed parts—such as strength and stiffness—while contributing to circular economy goals. Featured developments include:

AIMPLAS will also introduce MAGAYA, a project aiming to upcycle apple pomace — a by-product of cider production — into a biodegradable biopolymer suitable for MEX (material extrusion) 3D printing. This initiative addresses the environmental impact of FDM (Fused Deposition Modeling) by offering a sustainable alternative with a reduced carbon footprint.

The ECOFAP project targets the recovery of tanned leather waste from the footwear industry, transforming it into new 3D-printable materials. The goal is to enable the additive manufacturing of shoe soles and heels using recycled leather, fostering circularity in the fashion and footwear sectors and reducing landfill disposal.

Finally, REALISTIC focuses on producing lifelike anatomical models using advanced polymeric materials for personalized surgical planning. These 3D models replicate complex geometries of organs and orthotic devices, offering medical professionals realistic tools to optimize treatment strategies and reduce procedural risks.

Through its participation in Formnext 2025, AIMPLAS reaffirms its commitment to advancing sustainable, functional materials for additive manufacturing and bridging applied research with industrial implementation.

Subscribe to our newsletter. Just insert your e-mail and you will receive the latest news.