30 November, 2023

30 November, 2023AIMEN Technological Center has led an innovative European project aimed at researching and developing new technologies that allow efficient and effective repair of aeronautical parts made of thermoplastic composite, an increasingly used material.

The future of the aeronautical industry relies on the development and implementation of materials such as thermoplastics to make components lighter and more cost-effective. However, the technology and knowledge needed to address the challenges of repairing these materials are currently lacking.

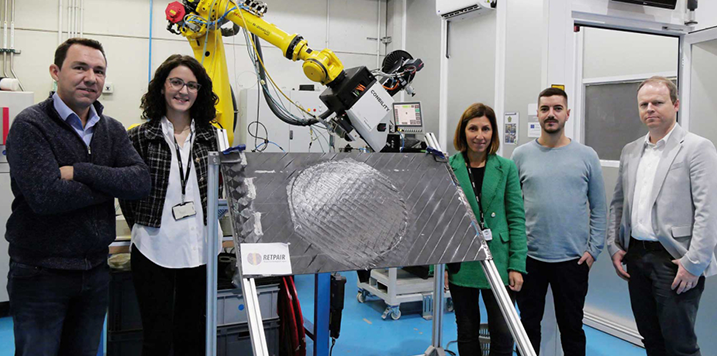

In this context, the RETPAIR project, which involved CT Engineers, Msquare GmbH, and Airbus Operations GmbH, has developed new high-performance, flexible, cost-effective, automated, and robotic technologies to replace and repair thermoplastic composite parts during the manufacturing phase, potentially applicable to in-service repairs.

To ensure the quality of the repair, critical process parameters have been monitored and controlled, and the applicability of the new technologies in different damage scenarios has been investigated.

Within the European RETPAIR project, new high-performance, flexible, cost-effective, automated, and robotic technologies have been developed to replace and repair components made of thermoplastic composite.

In addition to leading the project, AIMEN has worked on the application of additive manufacturing-based technologies as a repair strategy, using a layer-by-layer repair approach to regenerate damage in situ. As a result, the technological center will leverage repair design principles and methodology, providing high-tech consulting services to the industry and technological support to manufacturers of composite materials.

The developments from RETPAIR have resulted in flexible and precise repair technologies for high-performance and quality solutions, contributing to the growing use of thermoplastics in the industry. Although the project is originally oriented to address the problem of repairing aircraft parts made of this material, the innovations developed will be cross-sectoral and can be implemented in other industries such as automotive, wind energy, or civil engineering applications.

Source: Interempresas.

Subscribe to our newsletter. Just insert your e-mail and you will receive the latest news.