02 July, 2021

02 July, 2021PANGEA Aerospace, an innovative company developing the most efficient and modern rocket engines to tackle the challenges of a transforming space industry, and AENIUM, an engineering company specialized in Additive Manufacturing technologies and complex material science, seal an industrial partnership for the development and industrialisation of advanced combustion devices focused on advanced 3D printed processes and materials.

The agreement formalized between both companies ensures a breakthrough in engineering complex combustion devices and drives the analysis of different types of advanced super alloys so far untreated for the most demanding applications within the space sector.

PANGEA assigns the R&D, manufacturing and industrialization of their new Aerospike demonstrator to their consortium for achieving a successful hot-fire test by the end of 2021.

In addition, the partnership will also bring to the EU market the first GRCop 42 industrialised unit to enable other space companies to access the most advanced propulsion solutions through additive manufacturing.

For Adrià Argemi, CEO of Pangea Aerospace, "“Aenium is the perfect partner to advance quicker into our roadmap, and we are very excited to sign an agreement with a cutting-edge additive manufacturing start-up like them. The agreement with Aenium goes beyond shared exclusive capabilities on GRCop42 in Europe, a copper material specifically developed for rocket engines-. Aenium also brings an unmatched expertise and R&D capability in processes and materials. GRCop42 based alloys are one of the key solutions that allow us to solve the thermal challenges of an aerospike nozzle rocket engines. We are now ready to offer this unique capability to all the European aerospace sector.”

GRCop-42 is a high conductivity, high-strength alloy for use in high heat flux applications such as liquid rocket engines and other combustion devices. This NASA-developed copper-chrome-niobium alloy was developed for harsh environments specific to regeneratively-cooled combustion chambers and nozzles with good oxidation resistance.

Aerospike, GRCop42 and additive manufacturing

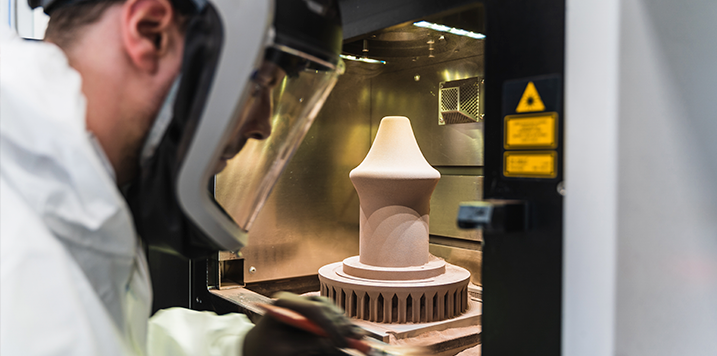

Pangea Aerospace is developing the long sought-after aerospike nozzle for rocket engines with a cutting-edge approach. The aerospike engine can radically transform space propulsion thanks to its higher efficiency (up to 15% than currently used rocket engines), reusability capabilities and very low-cost and rapid manufacturing. The company is currently manufacturing DemoP1 and will perform a hot-fire campaign in Q3 2021.

DemoP1 is a liquid oxygen and methane aerospike engine demonstrator designed to characterize and validate several key enabling technologies for future aerospike developments: the use of methane as a fuel, its manufacturing methodology, developed together with Aenium, a dual regenerative cooling system - exploiting both propellants to cool it down- and the design for reusability.

Several aerospike engines have been developed or conceptualized in history (J-2T, XRS-2200 and RS-2200) but none has ever flown. This is due to the engineering difficulties historically linked with aerospike nozzles: cooling and manufacturing. Now, Additive Manufacturing (AM) techniques and new materials such GrCop42 are enhancing the possibility to build a functional and economically viable aerospike engine at a fraction of the cost and time. The holy grail of propulsion is closer thanks to this agreement between Pangea Aerospace and Aenium.

Pangea Aerospace has already started the preliminary design of its larger, commercially ready aerospike engine and its subsystems, that will benefit from this collaboration.

Last, but not least, the agreement opens the door to a common service between Pangea Aerospace and Aenium for the European aerospace sector to access cutting edge materials. Aenium brings its expertise in material science and additive manufacturing process and Pangea Aerospace brings its expertise in propulsion system designs.

According to Miguel Ampudia, CIO of AENIUM, "this alliance will propel the next generation of reusable rocket engines also bringing the opportunity to the EU market to improve their combustion devices with the most innovative material science and qualified industrial additive manufacturing”.

Subscribe to our newsletter. Just insert your e-mail and you will receive the latest news.