27 September, 2016

27 September, 2016ADDITIVE is one of the integrated strategic research projects in the Basque Autonomous Community’s ETORGAI 2014 programme, budgeted at €3.35 million. The respective study is to be completed during this year of 2016.

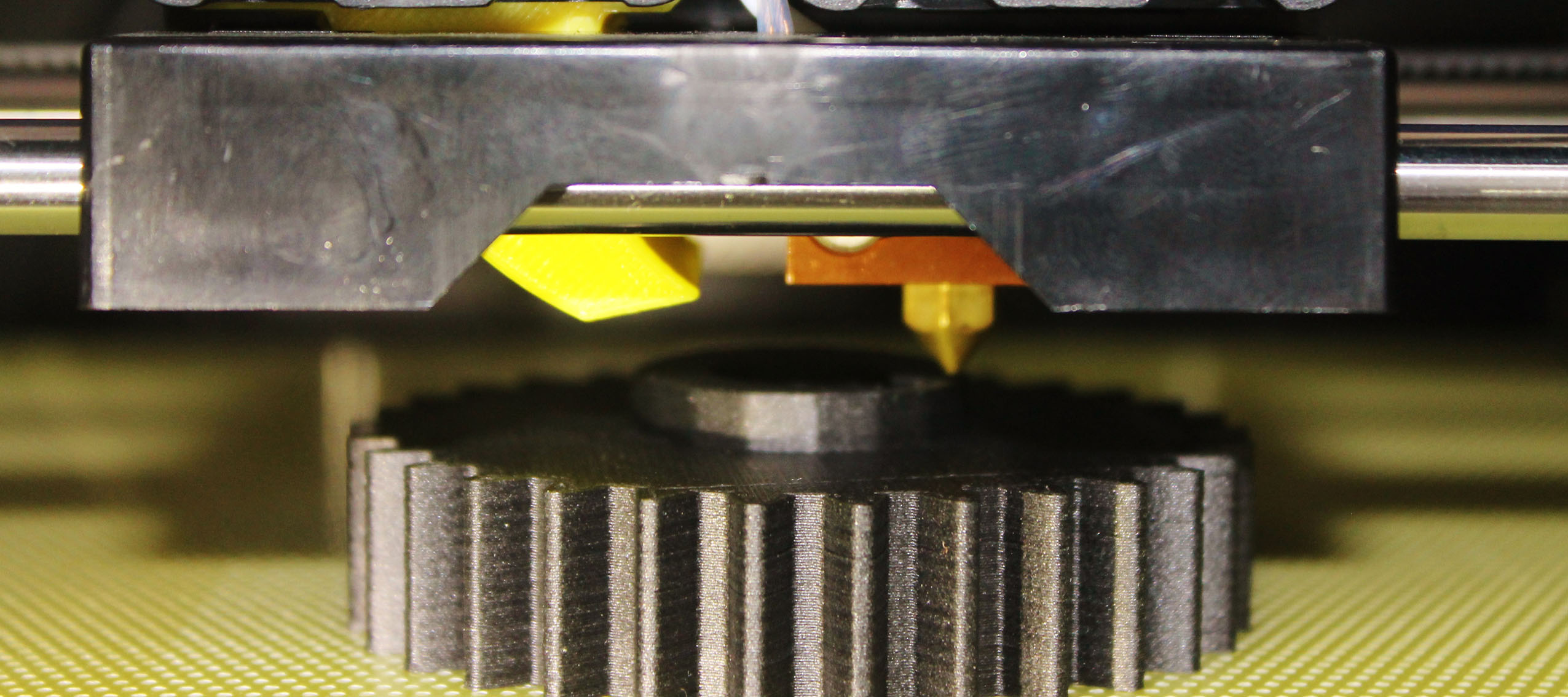

The aim is to research and develop a new generation of industrial components using game-changing additive manufacturing technology. The project specifically works with demonstrators for strategic sectors such as aeronautics, automotive and medicine via the use of SLM (selective laser melting) and LMD (laser metal deposition) technologies.

The project consortium comprises eight Basque companies led by CIE-INYECTAMETAL, together with CIE-Legazpi, Createch Medical, Aciturri Engineering, GAT Staff, Metallied Powder Solutions, Sisteplant and the AFM (Spanish Association of Manufacturers of Machine-Tools, Accessories, Parts and Tools), along with technological support from five research centres, IK4-LORTEK, IK4-AZTERLAN, Fundación CIE I+D+i, EGILE Innovative Solutions and INVEMA.

Research lines now under development:

1.- Development of raw materials for the different sectors involved

A core focus of the project is the development of raw materials in powder form that meet the specific processing requirements of additive technologies (LMD and SLM), to ensure that the developed materials behave properly, generating products of high metallurgical quality.

When the project is completed certified raw materials will have been developed for use in the automotive, aeronautics and medical sectors, with properties superior to those currently found on the market.

2.- Design, development and validation of parts made by means of additive manufacturing

The most suitable designs for parts manufactured during the project’s development will be studied from the functionality standpoint. Design rules are currently oriented toward manufacturing by means of mechanised technologies. When applied to additive manufacturing they do not take advantage of this technology’s potential.

LMD technology will be applied locally to tools worn down in aluminium injection and steel forging processes, the aim being to improve their durability.

This project will generate new design knowledge that takes advantage of additive technology potentials. Finally, all manufactured parts will be tested in real usage conditions, thereby providing information about their real behaviour. Design values can be obtained with the additive manufacturing process.

3.- Generation of design methodologies and feasibility

A major area requiring further exploration is the development of analytic methodologies to ascertain whether it is appropriate to manufacture with additive manufacturing technologies or traditional technologies. Analysis tools will therefore be developed to evaluate aspects such as number of parts, size, material and design, to assess the validity of manufacture using additive technologies and the respective economic feasibility. This will generate knowledge that can be used to optimise the use of additive technologies to make parts that are nowadays made using other technologies.

Subscribe to our newsletter. Just insert your e-mail and you will receive the latest news.